Electronic textiles

Electronic textiles have integrated functionalities such as communication, sensors, displays, or thermal management. In addition, electronic textiles can change their characteristics in response to external stimuli, for example mechanical, electrical, thermal and chemical changes in the environment.

Sportswear and health monitoring are among the main applications of electronic textiles. These applications require wearable sensors which can measure pertinent physiological parameters and provide health information in real time, while remaining unobtrusive, comfortable, low cost, and easy to operate and interpret.

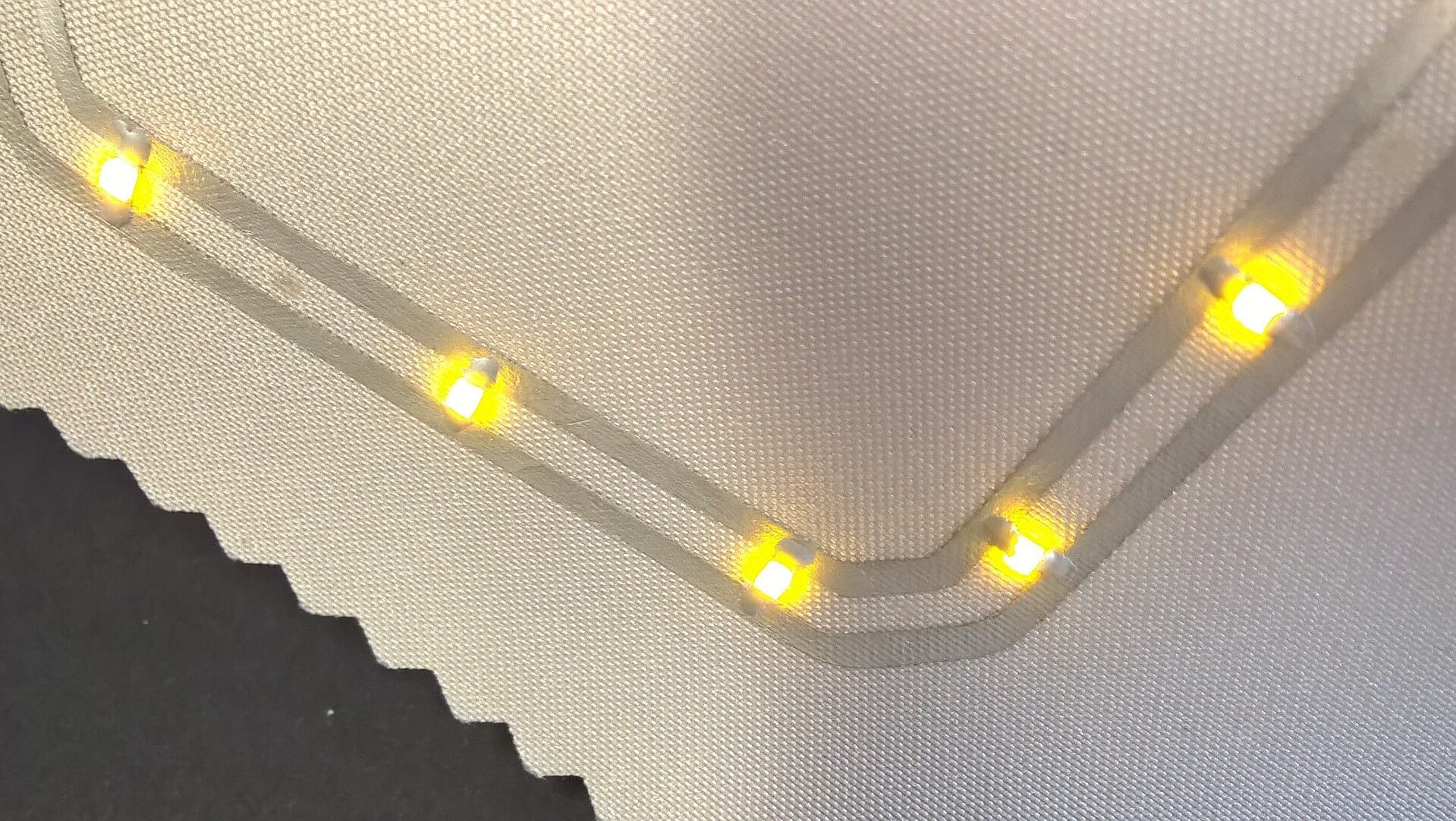

Today’s electronic textiles often use a combination of standard technology (rigid silicon chips and LEDs) with flexible, printed electronics. Component integration is one of the main challenges in this type of hybrid electronics.

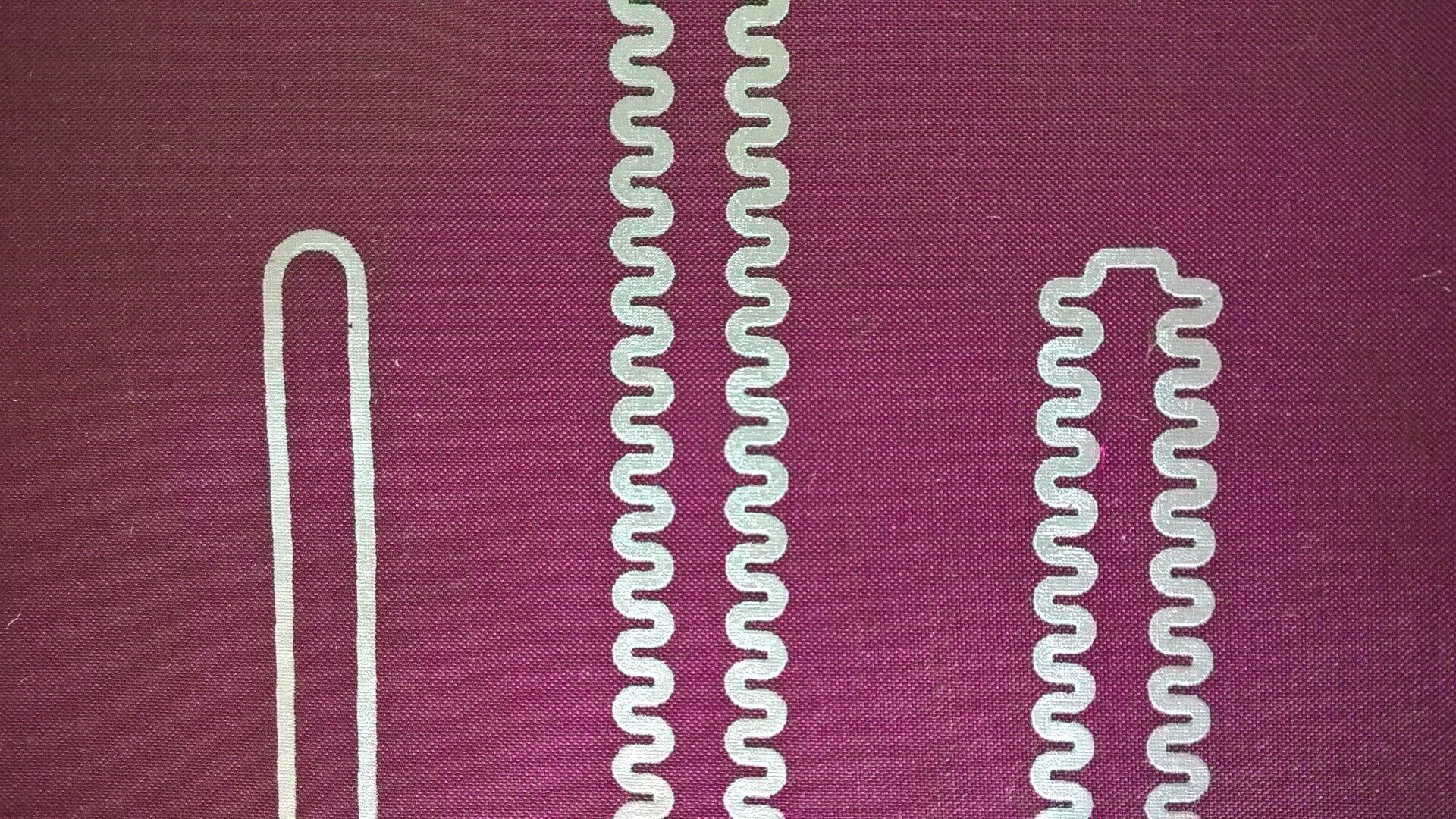

Materials available from DZP Technologies make it possible to create electronic circuitry directly on fabrics, without changing the fabric feel, performance and physical properties. For example, our silver conductive inks and adhesives produce conductive tracks with outstanding mechanical properties and environmental stability. There is no deterioration of the conductive properties, even after extended exposure to 85% relative humidity at 85 ̊C. Many of our inks produce circuitry which can withstand washing in domestic laundry machines.

The examples below illustrate how our materials can be used to create novel and exciting electronics for integration into garments.

Silver conductive tracks printed on silk, using conductive ink F0280. The tracks can replace wires and metallic yarns, and serve as the conductive component of sensors, heaters, lighting, antennas, and other circuitry.

Lighting circuitry printed directly on acrylic fabric, using conductive ink F0280. Conventional surface mount LEDs are attached to the tracks using conductive adhesive SA0850. This example illustrates how rigid components (such as surface mount LEDs) can be integrated with flexible components to create hybrid circuitry.

Lighting circuitry printed directly on organza silk to create an illuminated scarf which can be worn and folded many times without damaging the circuitry.

Graphene ink G0250 printed on acrylic fabric. The patterns can be used to form a strain sensor which detects movements of the fabric.