Internet of Things

Our electronic materials enable advanced, unique, and unconventional IoT solutions to secure market and technology leadership through innovation.

The Internet-of-Things (IoT) envisions a world of multiple connected sensors which monitor and record changes in physical objects or in the environment. The sensors can be used to perfect and monitor a manufacturing process, or they can be integrated into the end product to track its performance. Typically, these sensors measure properties such as strain, pressure, load, humidity, moisture, temperature, pH, and/or the presence of chemicals and gases.

IoT offers almost endless opportunities to bring intelligence into any everyday object or surface. It is transforming manufacturing as well as user experiences; it is underlying Industry 4.0 and shaping the development of artificial intelligence.

Using our products for IoT applications

Our conductive inks and other electronic materials can be used to produce a variety of sensors for practically any application. Silver conductive inks are the material of choice for producing conductive tracks which require metal-like conductivity. Carbon inks, on the other hand, are used to produce low-cost sensing components in strain and temperature sensors, and may also serve as low-cost interconnects where low currents are used.

We offer high performance, ready-to-use formulations which are compatible with mass production techniques. We also offer customised and specialty materials which create added value for our customers.

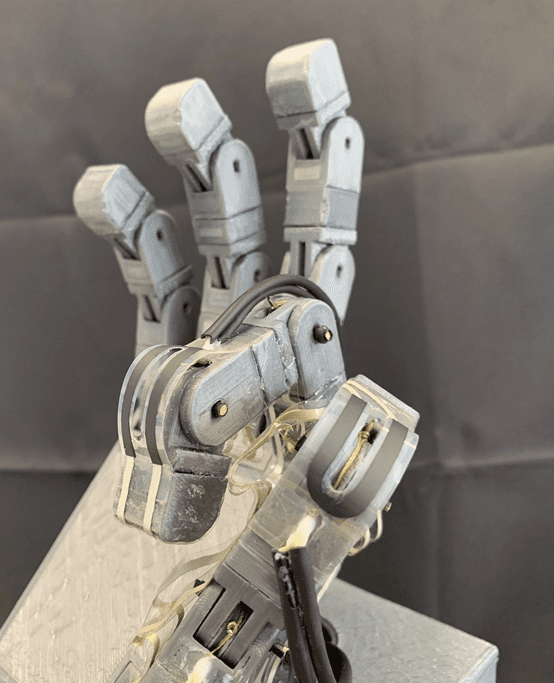

Robotic hand with a printed motion sensor using our silver conductive ink F0280, graphene stretchable ink G0360, and conductive adhesive SA0850.

What challenges can we solve?

Key challenges in developing sensors for IoT applications are manufacturability and the integration of different components.

It is not always easy to transform an everyday object into a “smart object”. While in many cases traditional, rigid electronics would provide a viable technical solution, some smart objects require specialist materials and expertise to produce electronics of unusual form factors.

The enhanced connectivity in the IoT means that there are increasing needs for electrical connections to collect data from the large number of sensors and individual devices. Whilst some of this data can be collected via wireless links, smart systems operating in electrically noisy environments may still require wired connections. These wires and electrical terminals can be bulky, taking up valuable space and adding weight.

Case study: printed sensor for condition monitoring

Applying sensors to a piece of equipment enables a move towards preventative and predictive maintenance that could immediately demonstrate improved operational efficiency and reduced downtime.

DZP Technologies is a partner in the Graphosite consortium which develops graphene printed sensors for condition monitoring of composite structures. To learn more about the project, click here.